Perovskite Flexible Solar Boom: Surprising 2025 Breakthroughs & Market Surge Ahead

Table of Contents

- Executive Summary: 2025 and the Flexible Perovskite PV Opportunity

- Key Market Drivers and Restraints Shaping Growth

- Breakthroughs in Perovskite Materials and Device Architectures

- Production Scalability: Manufacturing Innovations and Challenges

- Competitive Landscape: Leading Players and Strategic Partnerships

- Emerging Applications: Wearable, Portable, and Integrated PV Solutions

- Global Market Forecast: 2025–2030 Growth Projections

- Regulatory and Standards Roadmap for Perovskite PV

- Sustainability and Lifecycle Analysis: Environmental Impact

- Future Outlook: R&D Hotspots and Next-Gen Commercialization Pathways

- Sources & References

Executive Summary: 2025 and the Flexible Perovskite PV Opportunity

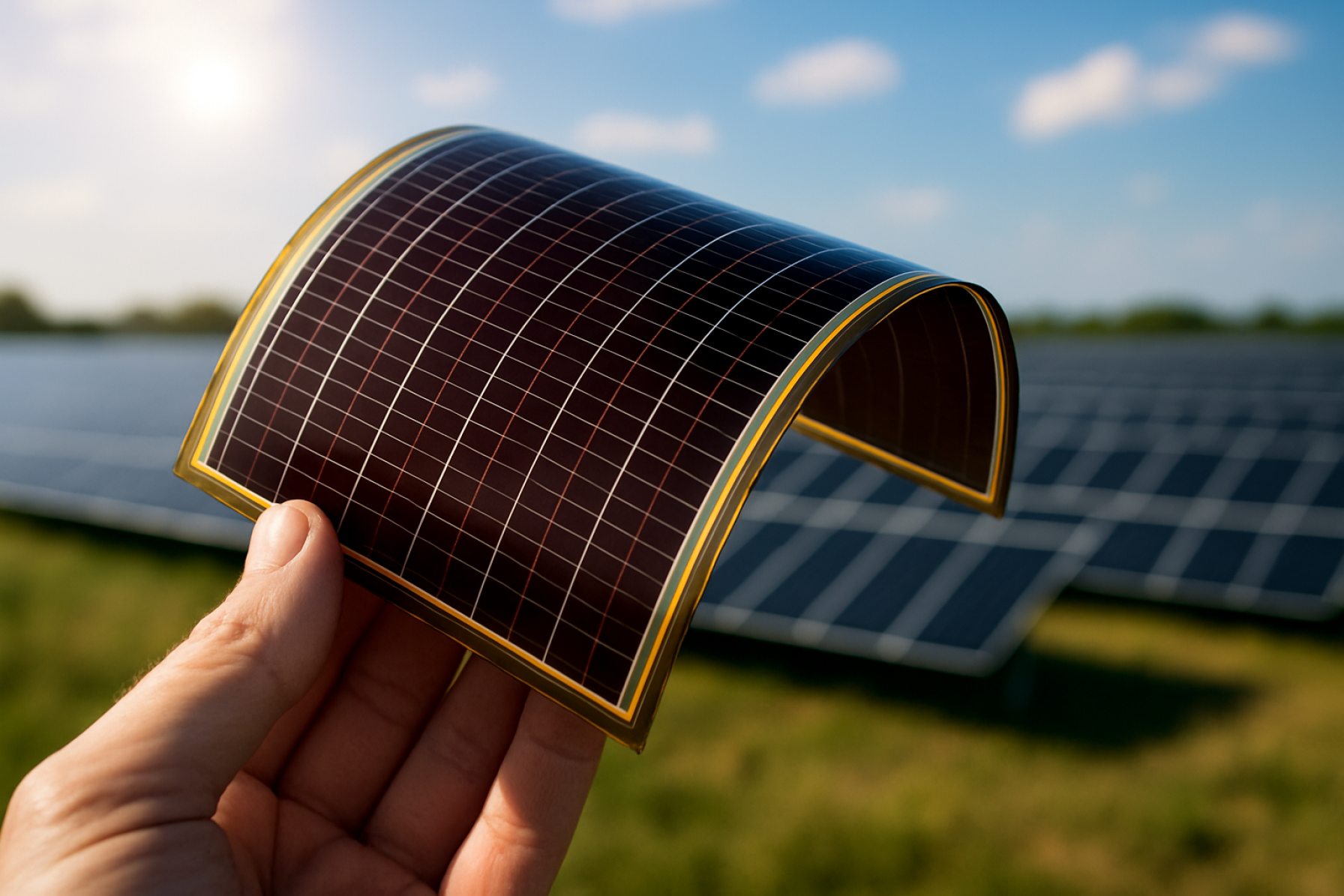

Perovskite-based flexible photovoltaics (PV) are poised to become a transformative segment of the solar energy industry by 2025 and beyond. This technology leverages the remarkable light-harvesting capabilities and tunable properties of perovskite materials, combined with flexible substrates, to create lightweight, bendable, and highly efficient solar modules. In recent years, perovskite solar cells (PSCs) have demonstrated rapid progress in both efficiency and stability, with laboratory-scale devices now regularly exceeding 25% power conversion efficiency. The unique advantages of flexible PSCs—such as roll-to-roll manufacturability, integration into curved surfaces, and potential for ultra-lightweight applications—are driving significant interest from both established PV manufacturers and innovative startups.

By 2025, key industry players are scaling up production and targeting commercial deployment of flexible perovskite modules. For instance, Oxford PV, a leading perovskite technology developer, has focused primarily on tandem cells but is also exploring flexible architectures for next-generation applications. Meanwhile, Saule Technologies has launched pilot production lines for flexible perovskite modules, delivering products for building-integrated photovoltaics (BIPV), IoT devices, and mobile electronics. Saule’s flexible panels, manufactured using inkjet printing, have been deployed in real-world pilot projects, demonstrating the potential of perovskite PV in diverse market segments.

In 2024, Saule Technologies announced commercial shipments of flexible perovskite modules for smart building applications, marking a significant milestone toward broader adoption. Simultaneously, Heliatek, a pioneer in organic and hybrid photovoltaics, has expanded its product lines to include flexible thin-film solar films, some of which incorporate perovskite technology in advanced prototypes. These efforts underscore the sector’s rapid transition from laboratory research to commercial reality.

Looking ahead to 2025 and the subsequent years, perovskite-based flexible PV is expected to find early adoption in niche markets where traditional silicon panels are unsuitable, such as wearables, portable electronics, aerospace, electric vehicles, and smart infrastructure. Industry roadmaps suggest that ongoing improvements in encapsulation, material stability, and scalable manufacturing will unlock broader applications and enable cost reductions. As companies like Saule Technologies move toward mass production, and others, such as Oxford PV, continue innovating, the outlook for flexible perovskite photovoltaics is highly promising for 2025, with significant growth anticipated through the decade.

Key Market Drivers and Restraints Shaping Growth

Perovskite-based flexible photovoltaics are emerging as a compelling alternative to conventional silicon-based solar technologies, driven by the need for lightweight, portable, and high-efficiency energy solutions. As of 2025, several key market drivers are accelerating growth in this sector, while certain technical and commercial restraints continue to shape its trajectory.

-

Market Drivers:

- High Efficiency Potential: Perovskite solar cells have demonstrated power conversion efficiencies exceeding 25% in laboratory settings, rivaling or surpassing traditional silicon cells. This notable progress is attracting significant investment and collaborative research from industry leaders such as Oxford PV, which is actively working on commercialization roadmaps for perovskite-based technologies.

- Flexibility and Lightweight Form Factor: The inherent flexibility of perovskite materials enables integration into bendable, lightweight substrates, opening new applications in portable electronics, building-integrated photovoltaics (BIPV), and even wearable devices. Companies like Heliatek are pioneering flexible thin-film solar modules, targeting architectural and mobility markets.

- Low-Cost Manufacturing: Perovskite solar cells can be produced using solution-based processes at low temperatures, promising significant reductions in manufacturing costs compared to silicon. This potential is being harnessed by firms such as Solliance, which collaborates with industrial partners to scale roll-to-roll production for flexible modules.

- Government and Institutional Support: Public and private funding initiatives are accelerating research, pilot production, and demonstration projects. For instance, the European Union supports several consortia focused on perovskite innovation through its Horizon Europe framework, benefiting industry actors across the value chain (European Commission).

-

Key Restraints:

- Stability and Durability: Despite efficiency gains, long-term operational stability remains a challenge. Perovskite materials are sensitive to moisture, UV radiation, and temperature fluctuations, which can lead to rapid degradation. Addressing these reliability concerns is a top priority for companies like GCL System Integration Technology and ongoing industry collaborations.

- Manufacturing Scale-Up: Transitioning from laboratory-scale prototypes to mass production introduces challenges in process uniformity, material quality, and cost control. Efforts by industry consortia and pilot lines, such as those coordinated by Solliance, aim to bridge this gap in the coming years.

- Regulatory and Environmental Concerns: The use of lead in some perovskite formulations has raised environmental and regulatory questions. Ongoing research is focusing on developing lead-free alternatives and improving end-of-life recycling processes to ensure compliance and market acceptance.

Looking ahead to the next few years, the sector is poised for rapid evolution as technical bottlenecks are addressed, pilot projects mature, and supply chains adapt to support commercialization. Stakeholders across the ecosystem—including module manufacturers, material suppliers, and research institutions—are expected to play crucial roles in navigating these drivers and restraints, ultimately shaping the future landscape of perovskite-based flexible photovoltaics.

Breakthroughs in Perovskite Materials and Device Architectures

Perovskite-based flexible photovoltaics continue to advance rapidly, with significant developments occurring in both materials engineering and device architectures as of 2025. The unique properties of metal halide perovskites—including high absorption coefficients, long carrier diffusion lengths, and tunable bandgaps—enable their integration into lightweight, flexible substrates, opening new frontiers for solar energy harvesting in applications beyond traditional rigid panels.

In the first half of 2025, research teams and companies have demonstrated flexible perovskite solar cells (PSCs) with power conversion efficiencies (PCEs) exceeding 20% in laboratory settings, a milestone that rivals conventional silicon-based devices. Key to these achievements are advances in perovskite composition and interface engineering, resulting in improved film uniformity, mechanical flexibility, and environmental stability. For instance, Oxford PV has reported progress in tandem architectures that can be adapted for flexible substrates, leveraging perovskite’s tunable properties to optimize light absorption while maintaining structural integrity under bending stresses.

Device architecture innovations have centered on the development of flexible electrodes and encapsulation strategies. Indium tin oxide (ITO) alternatives, such as silver nanowires and conductive polymers, are being adopted to enhance flexibility and reduce brittleness. Companies like Heliatek are scaling up flexible organic and perovskite-based photovoltaic modules for commercial and building-integrated applications, highlighting successful pilot projects in 2025 where flexible perovskite modules are installed on curved surfaces and lightweight structures.

Encapsulation remains a critical area, as perovskite materials are sensitive to moisture and oxygen. Recent advances by Toray Industries, Inc. in ultra-thin, multi-layer barrier films have extended the operational lifetimes of flexible PSCs, moving closer to the durability standards necessary for widespread deployment.

Looking forward, industry and research consortiums are targeting flexible perovskite module efficiencies above 23% and operational lifetimes exceeding 10,000 hours within the next few years. Collaborative initiatives, such as those led by National Renewable Energy Laboratory (NREL), are accelerating transfer from laboratory breakthroughs to scalable manufacturing processes. The outlook for 2025 and beyond suggests that flexible perovskite photovoltaics will play a crucial role in wearable electronics, transportation, and portable solar generators, with ongoing improvements in stability and manufacturability expected to drive commercial adoption.

Production Scalability: Manufacturing Innovations and Challenges

The production scalability of perovskite-based flexible photovoltaics is a central focus as the technology approaches commercial readiness in 2025. The inherent advantages of perovskite materials—such as solution processability and compatibility with low-temperature manufacturing—make them well-suited for large-area, roll-to-roll fabrication, a method critical for cost-effective mass production of flexible solar modules.

Several companies have demonstrated significant progress in scaling up manufacturing processes. Oxford PV has pioneered tandem perovskite-silicon solar cell technology and invested in scaling up production, with plans to achieve gigawatt-scale manufacturing capacities. While their primary focus is on tandem cells, their advancements in perovskite deposition and encapsulation techniques are directly transferrable to flexible formats. Meanwhile, Saule Technologies has established a pilot line for the industrial-scale production of flexible perovskite solar modules using inkjet printing, a technology that enables high-throughput and patternable manufacturing on plastic substrates.

Additionally, Heliatek is developing organic and hybrid organic-perovskite flexible solar films, leveraging vacuum deposition and roll-to-roll coating methods. Their Dresden-based manufacturing facility is among the most advanced for flexible photovoltaics in Europe and serves as a reference for scaling up perovskite-based lines.

Despite these advancements, several challenges remain. Uniformity and defect control in large-area coatings are critical for ensuring consistent performance and high yields, particularly as module sizes increase. Encapsulation and barrier technologies are under continuous refinement, as perovskite materials are sensitive to moisture and oxygen—factors that can degrade device performance over time. Companies are adopting multilayer barrier films and advanced lamination processes to extend operational lifetimes, as demonstrated by Saule Technologies in their commercial demonstrators.

Looking ahead, further automation, improved in-line quality control, and the adoption of recyclable or eco-friendly substrates will be key themes. Industry collaborations with equipment manufacturers and materials suppliers are accelerating the development of scalable, robust manufacturing platforms. The next few years are expected to see additional pilot lines and the first commercial deployments of lightweight, flexible perovskite modules in building-integrated photovoltaics (BIPV), portable electronics, and automotive applications, marking a crucial transition from laboratory to market for this promising technology.

Competitive Landscape: Leading Players and Strategic Partnerships

The competitive landscape for perovskite-based flexible photovoltaics in 2025 is characterized by dynamic innovation, strategic alliances, and increasing interest from both established solar manufacturers and emerging startups. As the field transitions from laboratory-scale breakthroughs to commercial prototypes and pilot production, several players are jockeying for leadership by leveraging proprietary materials, scalable deposition processes, and integration strategies for flexible electronics.

In 2025, Oxford PV remains a frontrunner, building on its expertise in perovskite-silicon tandem technologies and expanding R&D into flexible modules. The company has announced pilot programs to test flexible perovskite cells using roll-to-roll manufacturing, aiming to achieve commercial deployment in portable and wearable applications within the next few years.

Similarly, GCL System Integration Technology Co., Ltd. has broadened its partnership network to include research institutions focused on flexible substrates, aiming to accelerate the scale-up of perovskite solar films. Their joint ventures in Asia are targeting mass-production capabilities by 2026, with early field trials underway for building-integrated and off-grid applications.

Startups are also making significant contributions. Solarmer Energy Inc. continues to push the boundaries of flexible perovskite solar cells, reporting cell efficiencies above 20% under standard testing conditions and launching demonstration projects for ultra-lightweight, portable solar products.

Strategic partnerships are a hallmark of this emerging field. Notable is the collaboration between Heliatek and European industrial partners, focusing on large-area flexible perovskite modules for transportation and architectural applications. These partnerships aim to optimize encapsulation techniques and improve environmental stability—key factors for commercial viability.

Several major electronics manufacturers, such as Samsung Electronics, have publicly disclosed investments in next-generation flexible photovoltaics, integrating perovskite research into their broader strategy for self-powered wearable devices and smart surfaces. These investments are expected to yield prototype devices by 2027.

Looking ahead, the competitive landscape will likely be shaped by further collaborations between material suppliers, module manufacturers, and end-user industries (e.g., consumer electronics, transportation). The rapid pace of efficiency improvements and the drive toward scalable, low-temperature production processes position perovskite-based flexible photovoltaics as a disruptive force in the solar sector over the next several years.

Emerging Applications: Wearable, Portable, and Integrated PV Solutions

Perovskite-based flexible photovoltaics are at the forefront of next-generation solar technologies, offering unprecedented potential for integration into wearable, portable, and diverse built-environment applications. As of 2025, perovskite solar cells (PSCs) have seen rapid advancements in both efficiency and mechanical flexibility, largely driven by improvements in material stability and scalable fabrication methods.

Recent years have witnessed multiple milestones in the development of flexible perovskite modules. In early 2025, Oxford PV announced its latest generation of perovskite-on-silicon tandem cells, with a significant focus on transferring this efficiency leadership to flexible substrates. Meanwhile, Solliance Solar Research has reported roll-to-roll manufacturing of flexible perovskite modules, demonstrating operational stability over 1,000 hours under continuous illumination and bending tests, vital for real-world wearable and portable applications.

Commercial players are increasingly targeting integrated solutions. Heliatek and GCL System Integration Technology Co., Ltd. have accelerated pilot production of semi-transparent and ultra-lightweight perovskite modules intended for smart textiles, backpack-integrated chargers, and self-powered IoT devices. These modules typically achieve power conversion efficiencies in the 15–20% range, with thicknesses under 100 micrometers, and can be laminated onto curved or flexible surfaces without significant loss in performance.

On the technology front, flexible perovskite solar films are being engineered for high environmental durability, a critical requirement for wearables and portable gadgets. Toray Industries, Inc. is collaborating with partners to develop encapsulation films and barrier layers that can extend device lifetimes beyond five years, addressing one of the main historic hurdles for perovskite adoption in consumer applications.

Looking ahead, the sector is expected to see further cost reductions through scalable printing and coating processes, as demonstrated by 3M and Kuraray Co., Ltd., who are supplying specialty materials for rollable solar modules. The integration of flexible perovskite photovoltaics into wearables, building facades, and off-grid portable electronics is anticipated to accelerate, with several companies projecting commercial product launches as early as 2026. This positions perovskite-based flexible PVs as a transformative solution for energy autonomy across a broad spectrum of emerging applications.

Global Market Forecast: 2025–2030 Growth Projections

The global market for perovskite-based flexible photovoltaics is poised for notable growth in the period from 2025 to 2030, underpinned by rapid advances in material stability, upscaling, and manufacturing technologies. As of early 2025, a confluence of pilot-scale production, commercial partnerships, and increased R&D investments is setting the stage for expanded market presence beyond niche applications. Companies and organizations at the forefront, including Oxford PV, Solliance, and Heliatek, are actively showcasing flexible perovskite solar modules with power conversion efficiencies regularly surpassing 20%, a significant milestone for market viability.

The surge in perovskite PV interest is also evident from large-scale demonstrator projects. For instance, Solliance has recently reported semi-industrial roll-to-roll manufacturing lines for flexible perovskite modules, highlighting a transition from laboratory-scale to industrial-scale processes. These efforts are anticipated to yield commercial-grade, flexible solar products capable of integration into building materials, vehicles, and portable electronics by late 2025 and beyond.

Partnerships with established photovoltaic manufacturers are accelerating commercialization. Oxford PV has announced collaborations to scale up perovskite-silicon tandem modules, while Heliatek is piloting flexible solar films for building-integrated applications. Industry projections suggest that by 2026–2027, flexible perovskite solar modules may begin capturing measurable shares of specialty and off-grid energy markets, particularly where lightweight or conformable solar solutions are required.

The period to 2030 is expected to witness exponential growth in deployment volume, contingent on continued improvements in operational stability and environmental durability. Industry roadmaps from consortia such as Solliance point to targets of 25% efficiency and lifetimes exceeding 20 years under real-world conditions by 2028. These milestones are essential for cost competitiveness with traditional silicon and other thin-film PV technologies. Furthermore, the scalability of solution-based and roll-to-roll printing processes is projected to drive down module costs, opening new markets and applications.

Overall, the market outlook for perovskite-based flexible photovoltaics between 2025 and 2030 is optimistic, with the sector on the cusp of moving from R&D and pilot production to broader commercial adoption. Success will hinge on the ability of manufacturers to meet durability and efficiency benchmarks, while capitalizing on the inherent advantages of flexibility, lightweight design, and aesthetic versatility.

Regulatory and Standards Roadmap for Perovskite PV

The regulatory and standards landscape for perovskite-based flexible photovoltaics is fast-evolving, reflecting the technology’s transition from laboratory research to commercial pilot projects and early market deployment. As of 2025, governmental agencies, international standards organizations, and industry consortia are actively working to establish frameworks that ensure product safety, performance reliability, lifecycle sustainability, and market acceptance for these next-generation solar modules.

A central focus is harmonizing test protocols for durability and stability, as perovskite materials are known for their sensitivity to moisture, oxygen, and thermal stress. The National Renewable Energy Laboratory (NREL) is collaborating with global partners to adapt and expand existing IEC (International Electrotechnical Commission) standards, such as IEC 61215 and IEC 61730, to address the unique environmental and mechanical challenges posed by flexible perovskite PV modules. These adaptations include new stress-testing regimes for repeated mechanical flexing and rolling, as well as protocols for encapsulation integrity and long-term performance under real-world conditions.

In Europe, the Helmholtz-Zentrum Berlin (HZB) and partners are contributing to the development of guidelines for sustainability assessments and end-of-life management, a crucial concern given the potential presence of lead in many perovskite formulations. Proposed regulatory frameworks increasingly require transparent supply chain documentation and compliance with the EU’s Restriction of Hazardous Substances (RoHS) directive, as well as evolving waste electrical and electronic equipment (WEEE) rules.

Major manufacturers, such as Oxford PV and Solaronix, are engaging with standardization bodies to ensure that their flexible perovskite modules meet or exceed emerging certification criteria. For example, Oxford PV has announced its intention to pursue IEC certification for its tandem and flexible perovskite products, targeting not only laboratory benchmarks but also performance metrics relevant to building-integrated photovoltaics (BIPV) and portable electronics markets.

Looking ahead to 2026 and beyond, it is expected that new international standards specifically tailored for perovskite-based flexible PV will be published, potentially through the IEC or the International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS). These standards will be instrumental in guiding insurance, bankability, and broader commercialization efforts. Regulatory bodies in Asia, such as the New Energy and Industrial Technology Development Organization (NEDO) in Japan, are also investing in pilot projects and policy frameworks designed to accelerate safe and responsible deployment of flexible perovskite technologies.

- 2025 will see pilot certifications, data-sharing consortia, and testbed projects drive the first wave of regulatory-compliant flexible perovskite PV products.

- Stakeholder engagement between manufacturers, regulators, and standards organizations is crucial for rapid standards evolution and market entry.

- Environmental, health, and safety (EHS) considerations—especially regarding lead and recycling—are shaping both policy and product design in the sector.

Sustainability and Lifecycle Analysis: Environmental Impact

Perovskite-based flexible photovoltaics are rapidly advancing, with significant focus on sustainability and lifecycle environmental impact as these technologies approach large-scale commercialization. In 2025, the imperative for eco-friendly solar solutions coincides with stricter regulatory frameworks and growing consumer demand for low-carbon energy products. Perovskite solar cells (PSCs), especially those fabricated on flexible substrates, promise reduced energy payback times and resource usage compared to traditional silicon photovoltaics, but their lifecycle sustainability is contingent on materials choices, fabrication processes, and end-of-life strategies.

A key sustainability advantage of perovskite-based flexible photovoltaics lies in their low-temperature manufacturing processes, which require less energy than conventional silicon wafer production. Companies such as Oxford PV and Microquanta Semiconductor are advancing roll-to-roll processing and inkjet printing techniques for perovskite layers, reducing both carbon footprint and material wastage. Flexible substrates – commonly polyethylene terephthalate (PET) or metal foils – further lower the embodied energy of the final module, although the recyclability of these substrates remains a concern.

The environmental profile of perovskite photovoltaics is also shaped by the chemical composition of the perovskite absorber. Most high-efficiency perovskites contain lead, raising concerns about toxicity and end-of-life leaching. Industry bodies such as the International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS) are actively assessing best practices for encapsulation and recycling to mitigate these risks. Research groups and manufacturers are exploring lead-free perovskite compositions, but commercial-scale efficiencies remain lower than their lead-based counterparts as of 2025.

Lifecycle analysis conducted in pilot manufacturing lines indicates that perovskite-based flexible modules can achieve energy payback times below one year, outperforming most crystalline silicon panels. For example, Heliatek reports that its flexible organic photovoltaic modules, which share similar roll-to-roll production lines with perovskites, achieve payback periods of 3-12 months, depending on installation location. This bodes well for scalable perovskite production, provided toxicological issues are addressed.

Looking ahead, major players in the sector are preparing to implement take-back programs and closed-loop recycling schemes as part of their product stewardship commitments. Solaronix and Oxford PV have both announced research partnerships aimed at developing safe, efficient recycling and materials recovery processes specifically for perovskite-based modules. These initiatives are expected to become industry standards within the next several years, driving the sector toward a more circular and sustainable photovoltaic lifecycle.

Future Outlook: R&D Hotspots and Next-Gen Commercialization Pathways

Perovskite-based flexible photovoltaics are poised at a critical juncture in 2025, with research and commercialization efforts accelerating towards next-generation solar technology. In recent years, perovskite solar cells (PSCs) have demonstrated remarkable progress, achieving laboratory efficiencies above 25% for single-junction devices and over 30% for tandem configurations. The flexibility of these devices, combined with their lightweight and potentially low-cost roll-to-roll manufacturability, positions them as key contenders for portable, wearable, and building-integrated photovoltaic (BIPV) applications.

One R&D hotspot is the enhancement of device stability, particularly for flexible substrates. Recent collaboration between Oxford PV and manufacturing partners has produced perovskite-silicon tandem modules with improved encapsulation and resistance to environmental stressors, paving the way for more robust flexible formats. Similarly, Solaronix has been actively advancing barrier films and printable interlayers tailored for flexible perovskite modules.

Material and process innovation remains central. Helianthos is spearheading scalable ink formulations and low-temperature deposition methods, which are essential for compatibility with flexible plastic substrates. GCL Technology Holdings is also investing in high-throughput production lines aimed at perovskite roll-to-roll manufacturing, emphasizing the transition from lab to pilot-scale demonstration in 2025.

On the commercialization front, several startups and established solar companies are targeting early market entry for flexible perovskite modules, focusing on niche applications such as IoT power supplies, e-textiles, and lightweight rooftop installations. SUNPLUGGED and Fraunhofer Institute for Solar Energy Systems are piloting flexible perovskite modules for integrated automotive and consumer electronics, with field trials expected to expand through 2025 and beyond.

Looking ahead, the next few years are expected to witness further improvements in operational lifetimes, with the industry targeting 10,000-hour benchmarks for flexible perovskite devices—a crucial threshold for commercial viability. Standardization efforts, spearheaded by organizations such as the International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS), are anticipated to accelerate qualification pathways and enhance investor confidence.

In summary, the confluence of advanced materials research, pilot-scale manufacturing, and targeted early applications is set to drive perovskite-based flexible photovoltaics from a promising laboratory technology to the threshold of commercialization in 2025 and the years immediately following.

Sources & References

- Oxford PV

- Saule Technologies

- Heliatek

- Solliance

- European Commission

- National Renewable Energy Laboratory (NREL)

- Solarmer Energy Inc.

- Heliatek

- Kuraray Co., Ltd.

- Helmholtz-Zentrum Berlin

- Solaronix

- New Energy and Industrial Technology Development Organization

- Microquanta Semiconductor

- Fraunhofer Institute for Solar Energy Systems